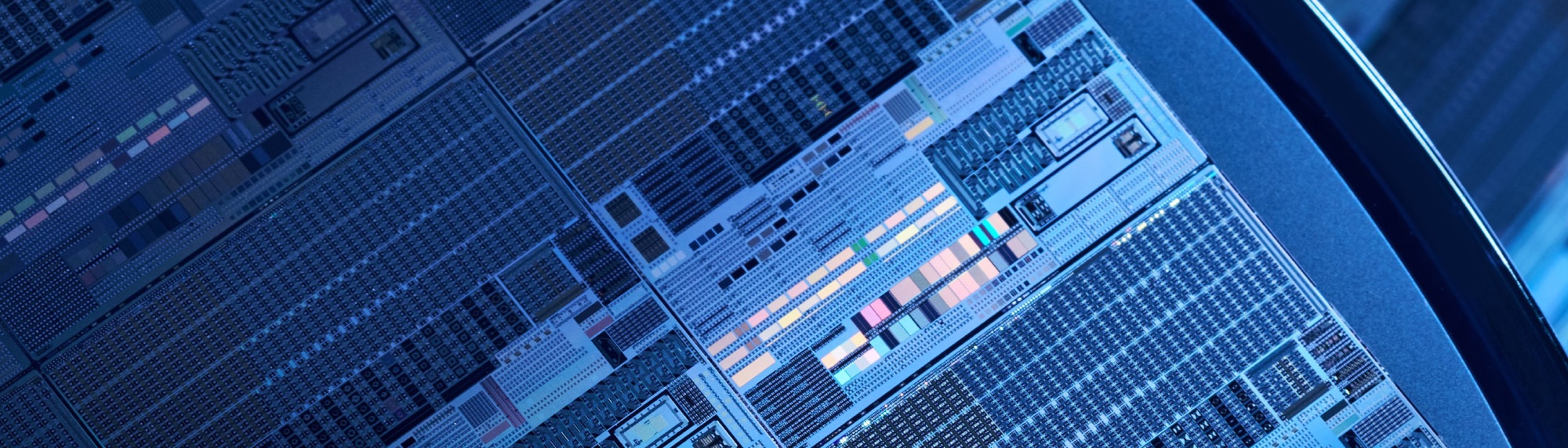

Semiconductor Manufacturing

Supporting Semiconductor Wafer Production and Fab Efficiency

Semiconductor Fabrication Demands Reliable, High‑Quality Power

Semiconductor fabrication is a massively complex process that relies on some of the most advanced and precise equipment ever created. Lead times for chips are longer than ever, with OEMs waiting up to 70 weeks.1 An unexpected power disruption can put productivity and sensitive systems at risk — representing millions in lost revenue.

1 Jabil Inc. corporate website, “Why the Chips are Down: Explaining the Global Chip Shortage,” accessed 12/2022

An Advanced Monitoring Solution

To prevent downtime and delays, semiconductor fabs need solutions to closely monitor power quality and environmental conditions at all times.

With a proactive monitoring strategy, semiconductor manufacturers can:

Detect Subtle Power Disturbances That May Signal Larger Issues

Get Instant Alerts to Changes in Environmental Parameters

Pinpoint the Root Causes of Issues to Accelerate Repairs

A Trusted Partner of the Semiconductor Industry for Nearly Two Decades

We deliver the solutions, expertise and vision to tackle the semiconductor industry’s toughest challenges.

PQube® 3 Delivers Essential Insights for the Semiconductor Industry

Our PQube 3 power analyzers are specifically designed to meet the unique challenges of semiconductor fab. These ultra-precise instruments are capable of measuring power quality and gapless harmonics up to the 150kHz supraharmonic range. Add the ENV2 module to keep watch on temperature, humidity, pressure and vibration.

Learn More