Keeping complex equipment firing on all cylinders is no easy task — especially when power quality issues arise. Power quality plays a significant role in avoiding plant downtime and ensuring systems run consistently and cost-effectively over the long term. However, it’s not always easy to detect power quality issues or identify their cause — especially across massive and/or geographically separated operating environments. That’s why critical facilities must take a proactive approach to managing power quality with 24/7 remote, always-on monitoring systems. These firmly fixed “eyes” on your equipment continually measure, detect and diagnose power quality issues across your entire portfolio — uncovering valuable insight that you can act on immediately or build into your planning.

Here’s how remote, cloud-based power quality measurement and monitoring helps you keep facilities operating profitably and at peak performance.

Boost workflow efficiency

Most facilities depend on multiple supervisors to keep operations running smoothly. But when you need to oversee a large fleet of equipment or multiple facilities at the same time — it can be difficult to keep everyone on the same page.

Remote, cloud-based monitoring puts an end to this problem and accelerates your workflow efficiency by helping you:

- Easily share insights, reports and dashboards between peers to keep everyone informed and on the right course

- Monitor all your equipment and facilities, all at once, from the convenience of your mobile device or desktop

- Securely access comprehensive information from one place to manipulate and analyze data, connect dots, view trends and create visualizations

- Keep teams updated about indicators and causes of inefficiencies and power disruptions

- Stay up to date with real-time data available on all your devices

- Analyze trends over time to connect dots and inform strategies

Avoid unplanned downtime

As systems become more advanced and efficient, downtime events could become more complex. Power outages aren’t the only culprit. Hidden power quality issues can damage equipment over time — leading to unexpected system failures and a lengthy diagnostic process that may require trial and error.

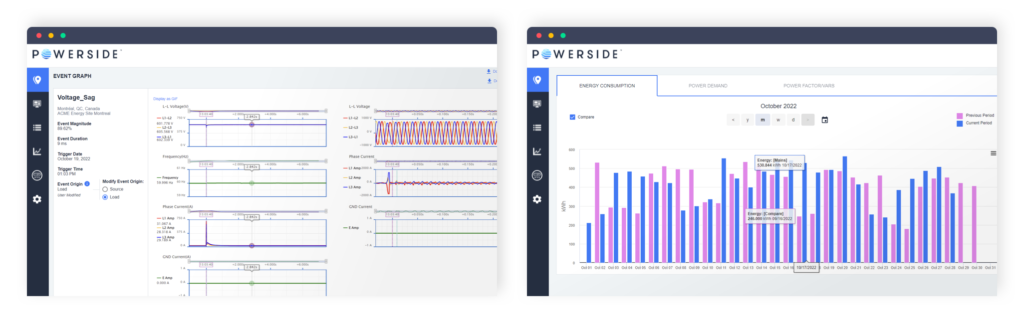

With real-time power quality alerts from a remote monitoring system, you can instantly detect and diagnose power quality problems to help take the guesswork out of repairs. Plus, by monitoring events over time, recurring patterns that contribute to downtime come to light.

Unplanned downtime events cost industrial manufacturers as much as $50B annually.1 Power quality insights can guide proactive prevention.

Extend equipment lifespan

Understanding the health of your system is critical to maintaining your equipment. A remote power monitoring system ideally should allow users to:

- Create alerts based on common issues, like system overheating, and determine their root causes — such as current overloads, unbalances, or harmonic distortion

- Monitor for power quality issues that have the most significant impact on equipment — like unbalanced loads that may damage motors or voltage deviations that disrupt sensitive equipment

- Leverage AI and machine learning to optimize diagnostics — helping you rapidly identify the direction and source of events like voltage sags

These capabilities allow you to quickly pinpoint the root cause of issues, accelerate response time and potentially prevent repeat occurrences — all to help keep equipment in peak condition for the long term.

Better understand energy consumption and costs

On average, 30% of the energy consumed in commercial and industrial facilities is wasted2 — and poor power quality is one reason. Poor power factor, unbalanced or nonlinear loads, voltage fluctuations, harmonics, and other common issues can all impact system resiliency and inflate your energy bill.

With the ability to monitor and analyze energy waste and power problems over time, you can:

- Improve energy efficiency

- Lower unnecessary energy usage and costs

- Manage peak loads and reduce demand charges

- Avoid power factor penalties from utility

- Achieve your sustainability goals

Don’t wait for a significant disruption to address power quality problems. With a remote monitoring approach, you can help avoid downtime, increase efficiency, and achieve more time- and cost-savings that enhance productivity.

Need a monitoring solution that can help you do all this and more?

Get started on your journey to operational efficiency with QubeScan from Powerside. Powered by AI and machine learning, QubeScan is the simplest way to capture, connect and convert real-time power quality and environmental data into actionable insights to support your goals.

Explore QubeScan today through our self-serve tutorial — and see all the ways it can help you take remote power monitoring to the next level.

1 https://www.forbes.com/sites/forbestechcouncil/2022/02/22/unplanned-downtime-costs-more-than-you-think/?sh=6ee837eb36f7

2 https://www.energy.gov/eere/buildings/about-commercial-buildings-integration-program