Project Summary

- Challenge: Voltage load imbalance

- Project Type: Power system analysis and simulation

- Equipment: PQube® 3 and PowerAct Active Harmonic Filter

The Situation

From power factor penalties to uncontrolled inrush currents, voltage imbalance can spark runaway costs, fast. Such was the case for an American manufacturer of lighting poles and traffic structures. Its fabrication process relied on flash welding, a technique that bonds metal parts using an electric arc. The catch? The flash welding machines—running on single-phase AC power—were used in sporadic durations and intervals throughout the day, causing significant system strain and load imbalance.

At the manufacturer’s current facility, a dedicated medium voltage (MV) feed kept this imbalance barely perceptible upstream. But the manufacturer planned to move its welding operations to a new facility—one without a direct MV feed.

Suddenly, their reliable setup was facing a critical power quality dilemma.

The Challenge

Due to the unpredictable nature of the flash welding power requirements, the new facility’s local utility said “no way” to supplying a direct low voltage 480V 3 phase feed. Instead, a medium voltage substation was specified to handle the load—an extremely expensive and time-consuming investment.

However, even with the MV substation, the issues of voltage imbalance would not be corrected. Without getting to the root cause of the imbalance and taking corrective action, the issue could lead to voltage instability and cause potential upstream issues for the utility grid.

The Solution

Enter Powerside’s full Power System Analysis. This comprehensive three-step service not only provided a deep dive into the manufacturer’s existing power systems to identify specific issues—it also simulated captured data against the future facility’s power profile to provide tailored next steps.

Let’s take a closer look.

Step 1. PQube® 3 Deployment

Powerside deployed PQube® 3 advanced power quality analyzer to the existing facility. After easily plugging the PQube 3 into the power system, the device captured the trending load and high-fidelity waveforms of the facility’s power profile under real-world conditions.

Step 2. Monitoring and Analysis

Over two weeks, the PQube® 3 monitored and logged every electrical fluctuation, spike, and dip. This rich dataset uncovered the root of the load imbalances, giving Powerside a clear view of the problem.

Step 3. Simulation and Solution Development

Powerside took the captured data and simulated it against the environment of the planned facility, testing different scenarios to find the right technical fix. After considering various solutions, Powerside identified the PowerAct Active Harmonic Filter as the ideal match for load balancing and mitigating the unique challenges of the flash welding process.

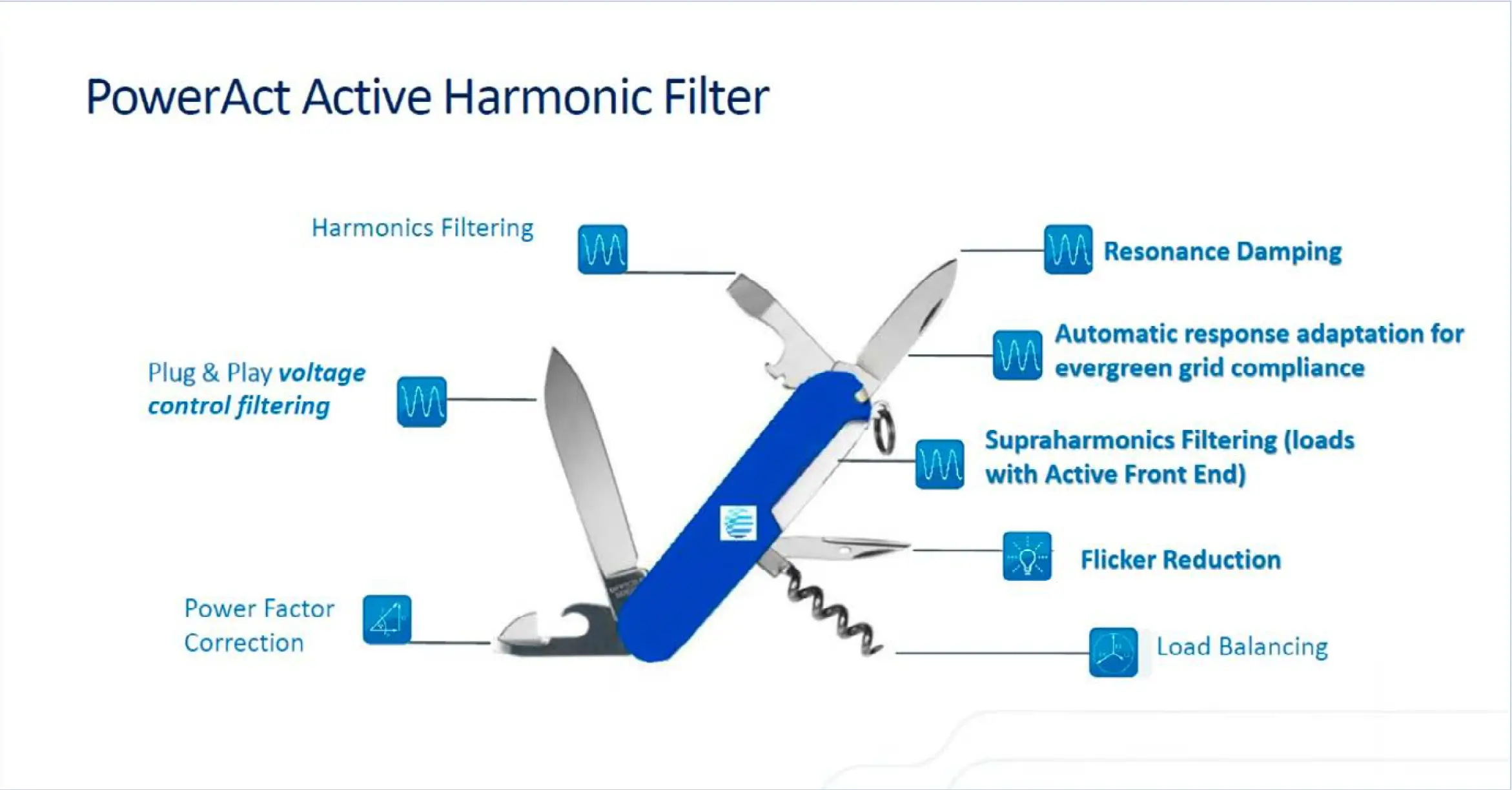

Figure 1: The PowerAct Active Harmonic Filter is a multi-tool for power quality, helping to maintain effective load balance, prevent equipment malfunctions, and boost overall efficiency.

The Results

Designed to mitigate various power quality phenomena, the PowerAct Active Harmonic Filter’s load balancing capabilities were ideal in this scenario. Harmonic filtering, power factor correction, grid compliance, resonance dampening, and more were simply added benefits that will continue to lend value to the manufacturer’s long-term operations.

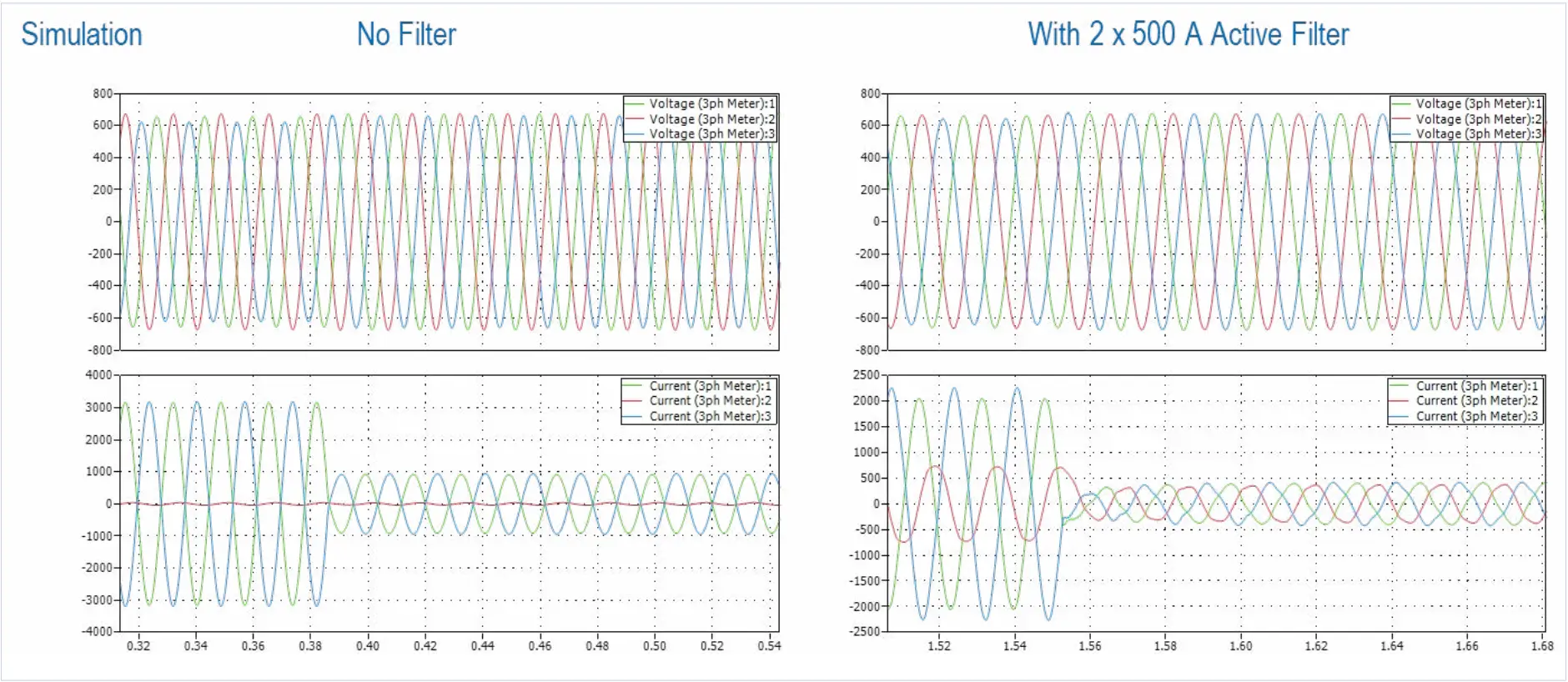

Figure 2: The simulated data shows the striking difference in voltage sags before and after the active filter is placed.

With the PowerAct Active Harmonic Filter in place, the manufacturer gained immediate and measurable benefits:

- Enhanced Load Balancing: Voltage sags were cut down (Fig. 2), bringing load imbalance from >10% to <3% and well within utility compliance requirements.

- Cost Savings: By balancing the load and improving power quality, the PowerAct filter ultimately bypassed the need for an expensive, dedicated substation, delivering 4X cost savings.

- Time Savings: No more waiting on new infrastructure—the filter made the move seamless, cutting down the time to go operational in the new facility.

Moving forward, the PowerAct Active Harmonic Filter will continue to correct the load imbalance caused by the flash welding process — all while adding extra protection against harmful power quality issues that could arise in the future.

Even the most complex electrical challenges have straightforward solutions. Uncover and solve your power quality issues with a Power System Analysis today.