Securing Emergency Power with Powerside’s PowerMVar and PowerAct Filter solutions

Most businesses think of power reliability in the context of service agreements, productivity and cost efficiency. But in healthcare, a consistent power supply is a matter of life and death. With U.S. electricity customers experiencing over eight hours of power interruptions on average in 20201 — the most since data collection began in 2013 — concern for the operation of critical medical equipment is warranted.

The National Electric Code (NEC) 700 and the Joint Commission on Accreditation of Healthcare Organizations (JCAHCO) mandate that hospitals have emergency power available within 10 seconds following a utility failure. The requirements specify that emergency backup power must be installed and regularly tested.

Managing electrical power quality (including power factor and harmonic distortion) under medical facility conditions, and with daily load variations, is complex. This application note considers special design considerations — which include Powerside’s PowerMVar and PowerAct correction solutions that circumvent the oversizing of gensets while ensuring reliable operation.

Falling into the trap of costly, over-engineered diesel back-up power

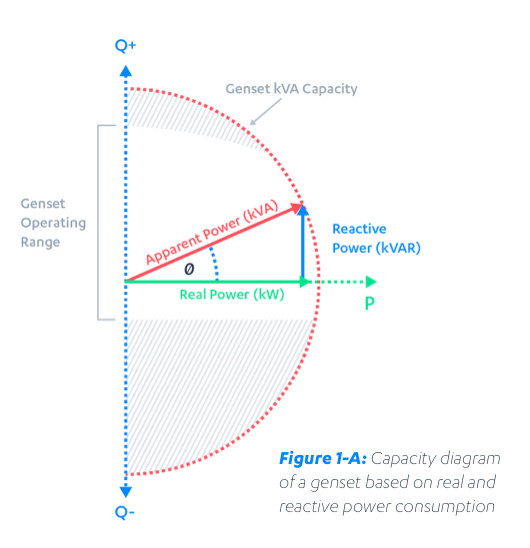

To ensure a maximum level of reliability, medical facilities are typically designed with redundant utility feeds and UPS backup for small critical loads. Should utility power outages occur, these facilities are equipped with diesel generators (gensets), often in redundant configurations. Gensets are frequently over-dimensioned not only to address future growth, but also to account for the problems associated with inductive and non-linear loads. This is because gensets are rated based on a maximum amount of apparent power they can supply, measured as kilo Volt-Amperes (kVA). Apparent power is the combination of:

- the real power (kWs) consumed by the load to operate

- plus the reactive power (kVAR) consumed by inductive loads such as motors and transformers.

As shown in figure 1-A, the higher the amount of reactive power (“Q”) drawn by the loads, the lower the available real power (“P”) from the generator. A facility with a lower power factor is one with multiple inductive loads drawing a high amount of reactive power.

Typically, such inductive loads would include:

- the central heating and cooling system

- distribution transformers

- elevators

- compressors in refrigeration units

- parking lights

- and other systems

Because of these considerations, the power factor of a facility can easily fall well below 0.9 and significantly reduce the real power (kW) available from the genset. In most municipalities, a power factor below 0.95 often incurs a power factor penalty from the electric utility, reflected on the facility’s electric bill.

How the PowerMVar addresses these challenges

Installing a PowerMVar capacitor bank is an inexpensive and effective solution to:

- correct power factor

- eliminate penalties and

- avoid the cost and space associated with the oversizing the diesel generators.

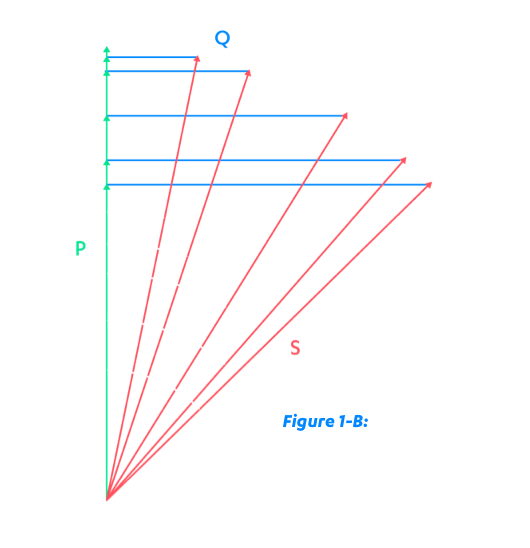

As shown in figure 1-B, correcting a power factor from .7 to .95 or higher can increase the available kW capacity of the genset by as much as 40-43%. It can also save penalties, accomplishing break-even on the cost of the capacitor bank within 12-18 months.

Reducing transitional and operational risks under diesel generator power

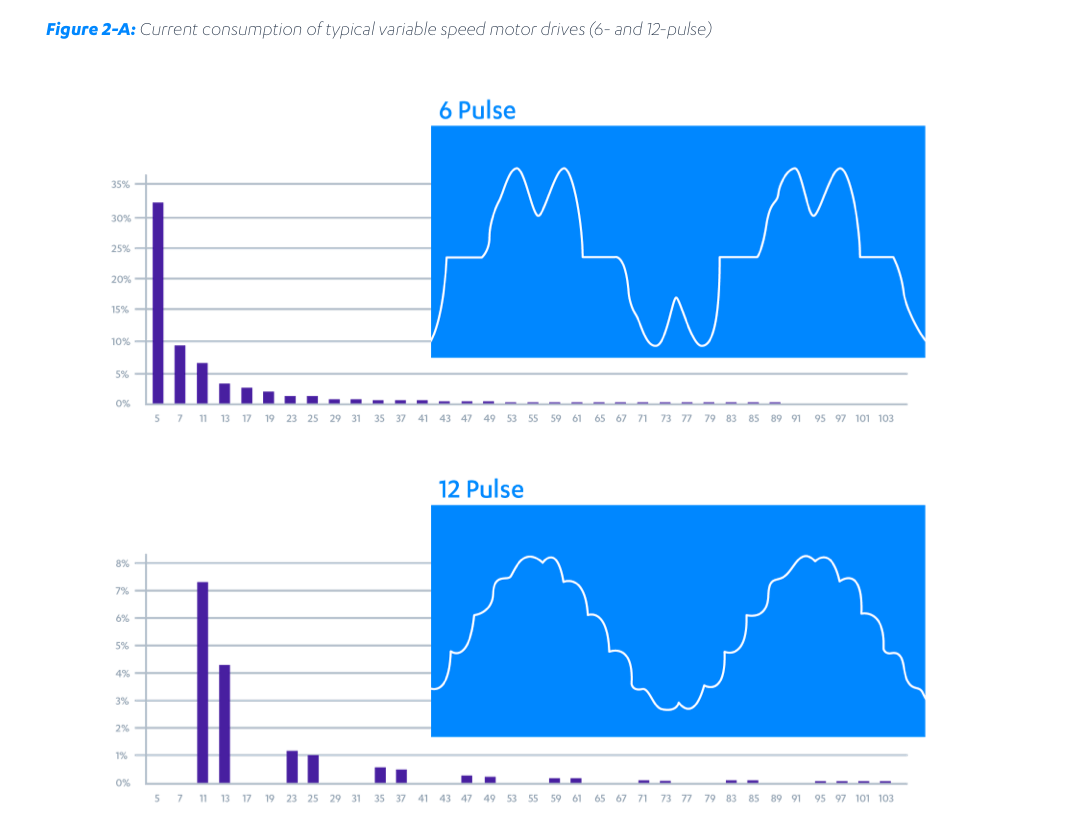

Another reason why gensets are frequently over-dimensioned is to provide a higher short-circuit current capacity and reduce the voltage distortion caused by the harmonic currents in electronic non-linear loads. Certain equipment consumes energy in pulses (figure 2-A) — including:

- high-power imaging machines (MRIs, scanners)

- monitoring units

- computers and communication systems

- uninterruptible power supplies

- LED lighting, etc.

This pulsing causes the voltage waveform to distort, at times to levels which exceed the safe operating levels set by IEEE Standard 519™-2014 for recommended practice and requirements for harmonic control in electric power systems. Because hospitals are critical facilities, IEEE 519 sets more stringent levels for power distortion to minimize the risk of equipment malfunction.

What can be done to address voltage distortion and ensure critical loads run reliably under emergency power?

A more economical and efficient solution is to absorb the harmonic currents inside the capacitor bank. PowerMVar can easily be configured to include a de-tuned filter reactor for harmonic dampening — or, in cases where particular frequencies are predominant, specifically tune reactors to absorb those dominant frequencies.

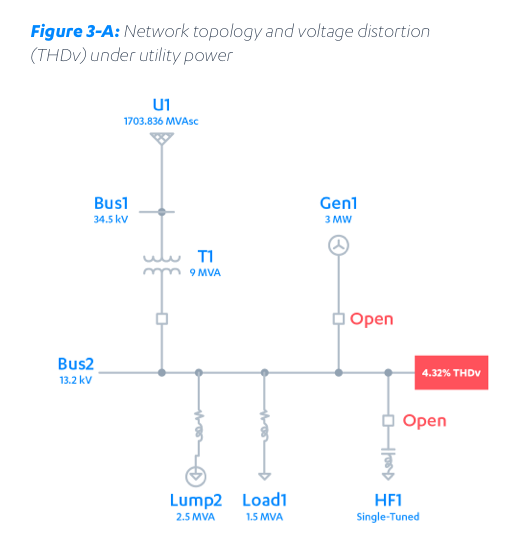

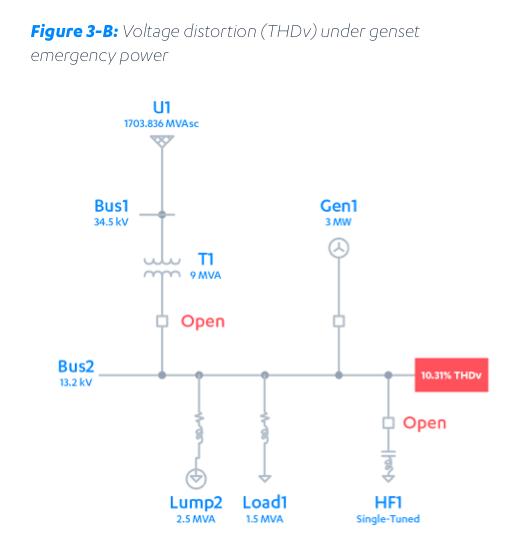

For example, Figure 3 shows a typical network configuration of a hospital under utility power (figure 3-A) and emergency genset power (figure 3-B).

The total voltage distortion (THDv) goes from 4.32 % under utility-fed power to 10.31% under emergency genset power. This increase in voltage distortion represents a potential risk during the transition to and in on-going operation under emergency power.

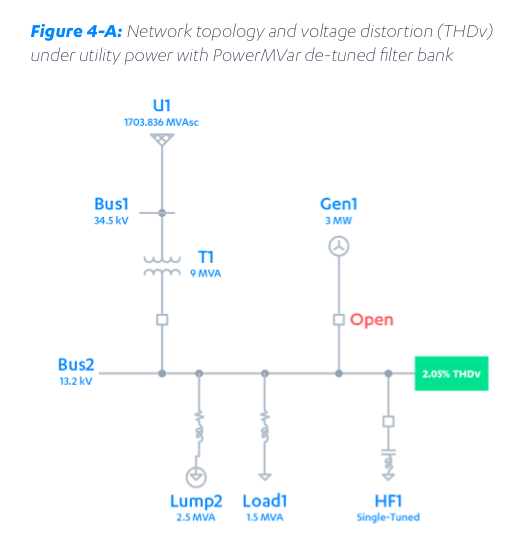

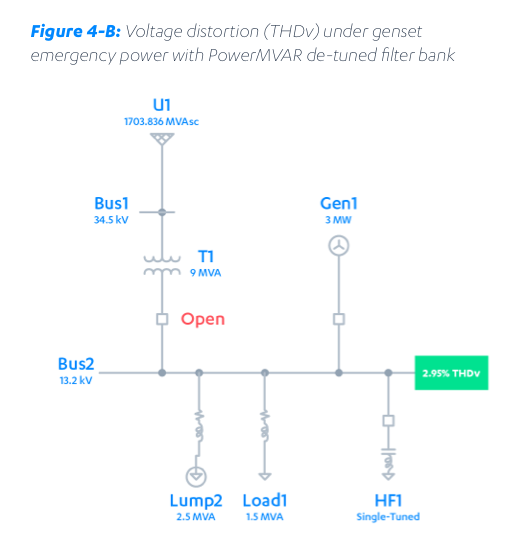

Figure 4 shows that by adding a 1500 kVar de-tuned PowerMVar filter bank, the THDv drops to 2.05 % under utility power (figure 4-A) and 2.95 % under emergency genset power (figure 4-B), which complies with the maximum allowable level of 3% THDv under IEEE-519.

Dynamic harmonic filtering with PowerACT

Capacitor/filter banks are the lowest cost of ownership power correction solution for installations where the load and harmonics vary slowly, requiring bank switching a few times per day. Another benefit: The degree of harmonic suppression available remains in approximate lockstep with the amount of power factor correction selected.

For facilities with abnormally high harmonic levels, or where the levels vary dynamically, or where the ratio of harmonic suppression to power factor correction required is not constant, an active harmonic filter should be considered in conjunction with static capacitor or filter banks.

Powerside’s PowerACT filter works much like a noise-cancelling headset — measuring network harmonics cycle by cycle, and dynamically injecting reactive currents in antiphase to eliminate them. The PowerACT filter is modular in design, and — in combination with PowerMVAR switched VAR compensation — is a highly efficient and versatile power factor and harmonic management solution for a dynamic load environment.

Reducing harmonics

Harmonics can also be reduced by installing equipment with lower harmonic emissions — most notably variable frequency or soft start motor drives. However, such equipment still generates harmonics at partial load, and can be more expensive, with lower efficiency.

The effects of harmonics can also be mitigated by oversizing some of the network components, particularly in distribution and emergency power, to provide a low harmonic impedance. However, this approach is costly, increases space requirements and leads to underutilized capacity.

Thanks to its sophisticated controls and numerous features, PowerACT brings several benefits to a power network:

- Provides sub-second management of voltage levels and distortion

- Helps reduce phase imbalance

- Reduces the risk of disturbances and interference

- Improves performance of imaging and other sensitive equipment

- Reduces equipment heating and prevents damage

Testing gensets: Remember to think “worst-case”

Finally, it’s appropriate to mention an important operational risk sometimes encountered when progressive load and harmonic growth eventually exceed an installation’s initial design specification.

Hospitals are required to test gensets regularly to ensure reliable performance upon demand. Genset testing is typically performed at night for risk reduction and operational reasons — i.e., when facility loads and harmonic levels may be well below the daytime peak. The problem here is that nighttime periodic tests may prove satisfactory in terms of power availability and general operation — yet gensets may fail, or medical equipment trip off, when subject to higher daytime peak operating loads and at higher current distortion levels.

In evaluating or upgrading power correction equipment for existing installations, it’s critical to consider worst-case projected conditions in the design and testing of both grid-connected and backup power operation so that the power source can transfer reliably under any supply or load conditions, at any time of day just not at night.

Conclusion

Medical centers are obligated to ensure power security for their critical loads under all circumstances. That’s why installing redundant utility feeds, backup diesel generators and UPS is the norm. However, unless those are regularly tested in their real, worst-case operating conditions, there is no assurance that the facility will operate reliably during a utility power outage. Keep in mind that loads such as cooling and ventilation, high-power imaging, lighting and other inductive and non-linear loads affect the power factor and themselves can create harmonic currents inside the facility’s power network. This reduces the power capacity available from the generator and distorts voltage waveforms.

Installing a PowerMVar filtered capacitor bank — and, in the presence of high harmonics, a PowerACT active harmonic filter — is a cost-effective, efficient and reliable solution to:

- avoid wasted genset capacity

- correct voltage distortion, and

- eliminate power factor penalty fees.

Appendix: PowerMVAR and PowerACT Overview

PowerMVar is a fully engineered metal-enclosed capacitor and filter system which provides reactive power compensation and harmonic filtering at medium voltage levels from 2kv to 38kv. Each system can be configured for tuned, high-pass or C-type filtering of harmonics generated by non-linear loads, or otherwise deployed filter ready for future addition.

PowerAct is an active filter available in a 125A wall mount enclosure or in a fully modular floor-mount cabinet which can grow up to 750A. The system operates at nominal voltages from 208V to 690V to provide active harmonic filtering, stabilize voltage, balance loads, and compensate for power factor via injection of reactive power. PowerAct incorporates a high-performance smart controller for maximum harmonic correction, and a 3-level IGBT Inverter topology with a dedicated cooling chimney for highest high-power high-temperature performance in the most compact footprint.

The result is a flexible, controlled and compact harmonic filter that is safe, easy to operate, compliant with standard communication protocols, and meets IEEE 519-2014 harmonic requirements.

Have a power quality challenge? Talk to us.

We’re here to help you work through the complexities of assuring power reliability in the healthcare environment.

Contact Us

United States

980 Atlantic Ave

Alameda (CA) 94501

1-888-736-4347

Canada

7850 Trans-Canada Highway

Saint-Laurent (QC) H4T 1A5

1-877-333-8392

1 U.S. Energy Information Administration, “U.S. electricity customers experienced eight hours of power interruptions in 2020,” November 10, 2021