Why Powerside got granular to reduce a customer’s utility penalties

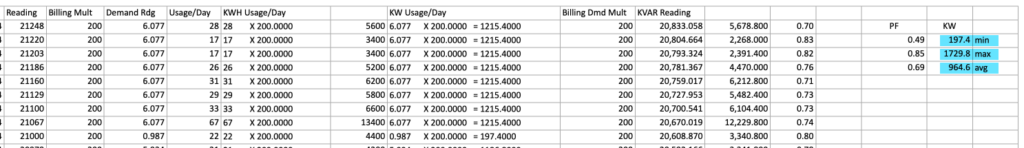

Recently Powerside was approached by an engineer looking to price a 1400kVAR 480V detuned capacitor bank for a grain elevator. Wanting to leave nothing to chance, we discussed the parameters of the project to be sure we had the best solution to restore the Power Factor and reduce the customer’s penalties. Our first step was to analyze about a year’s worth of data from the facility provided as daily data.

As we ran through the assumptions to determine the kVAR adjustment to make 0.95PF, we noticed a common misunderstanding/miscalculation. The daily Power Factor was provided as an average value, not based on the peak VARs required. This is significant, especially when plants are not running 24/7 and the transformer inductance artificially lowers the daily or monthly values of the Power Factor. This is particularly impactful when large motors in the system are at idle. Unfortunately, that’s not always easy to detect when the only data you have is a list of average daily data and min-max and average KW demand.

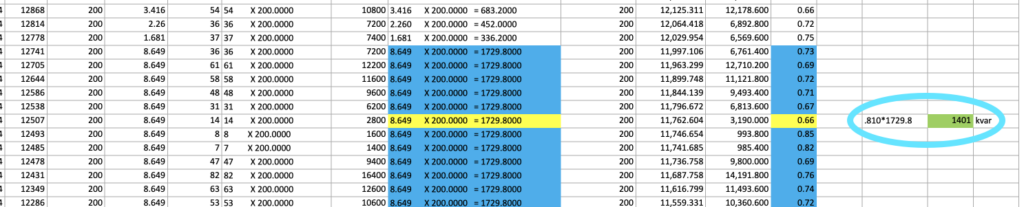

After reviewing the data and discussing the application, we could see that the 1400kVAR request was based on the peak power demand; however it was also based on the worst daily Power Factor average of 0.66 and the customer’s assessment of which capacitor bank would be the best choice to achieve 0.95 PF. What’s missing here is a look behind these daily PF numbers. If average Power Factor is low because loads are at idle for significant periods, the VAR adjustment needed during these periods would also be low.

There were no capacitors in the existing system, so we could be confident that nothing could improve the Power Factor itself other than perhaps running at optimum load for a longer period, which was not feasible. Powerside painstakingly analyzed all of the data provided and was able to bring the needed capacitor bank sizing down to 800kVAR while maintaining almost a unity Power Factor.

What can we learn from this experience?

How can we make sure that customers and engineers correctly determine the required kVAR adjustment and not base the size on the wrong assumptions?

Utilities look at Power Factor when billing two ways: on peak demand or as an average. For this customer, the proper solution is to consistently run a 200kVAR fixed unit to cover correction from the transformer at low load — and to have an additional auto-switching 600kVAR unit to further improve the efficiency of the system as power on the system increases. As a rule of thumb, for a 2500kVA transformer-fed system, 10% capacity converted to kVAR is always safe to assure minimal voltage rise.

Talk to Powerside for help with a wide range of capacitor bank systems that can be tailored to your application.