Whether you’re in the business of supplying power or running a business that consumes a lot of it, you’ll probably relate to any of these scenarios:

- High-tech equipment frequently reboots on its own

- Variable speed drives often affected by nuisance tripping

- Capacitor banks don’t seem to last long, and replaced sooner than expected

Each of these issues can produce costly consequences. There may be productivity impacts such as operations downtime, unsuccessful troubleshooting, excessive maintenance and repair efforts, or equipment replacement that yields no improvement. Even more alarming are the potential safety risks employees may be exposed to while working on the problem.

Naturally, attempts at resolution tend to focus solely on the equipment — which misses the true source of the problem: Poor power quality at the grid edge. A study by the Electric Power Research Institute highlighted the prevalence of power quality issues from an economic perspective: In the U.S. alone, power quality issues may be costing U.S. businesses, cumulatively, as much as $230 billion a year.1

The Cause and Effect of Power Quality Issues

Put simply, a technological generation gap has emerged in the flow of electricity as it moves from energy source to end use. Legacy grids weren’t built for the modern technologies that power energy-efficient industrial facilities, EV charging stations, and smart devices demanded today.

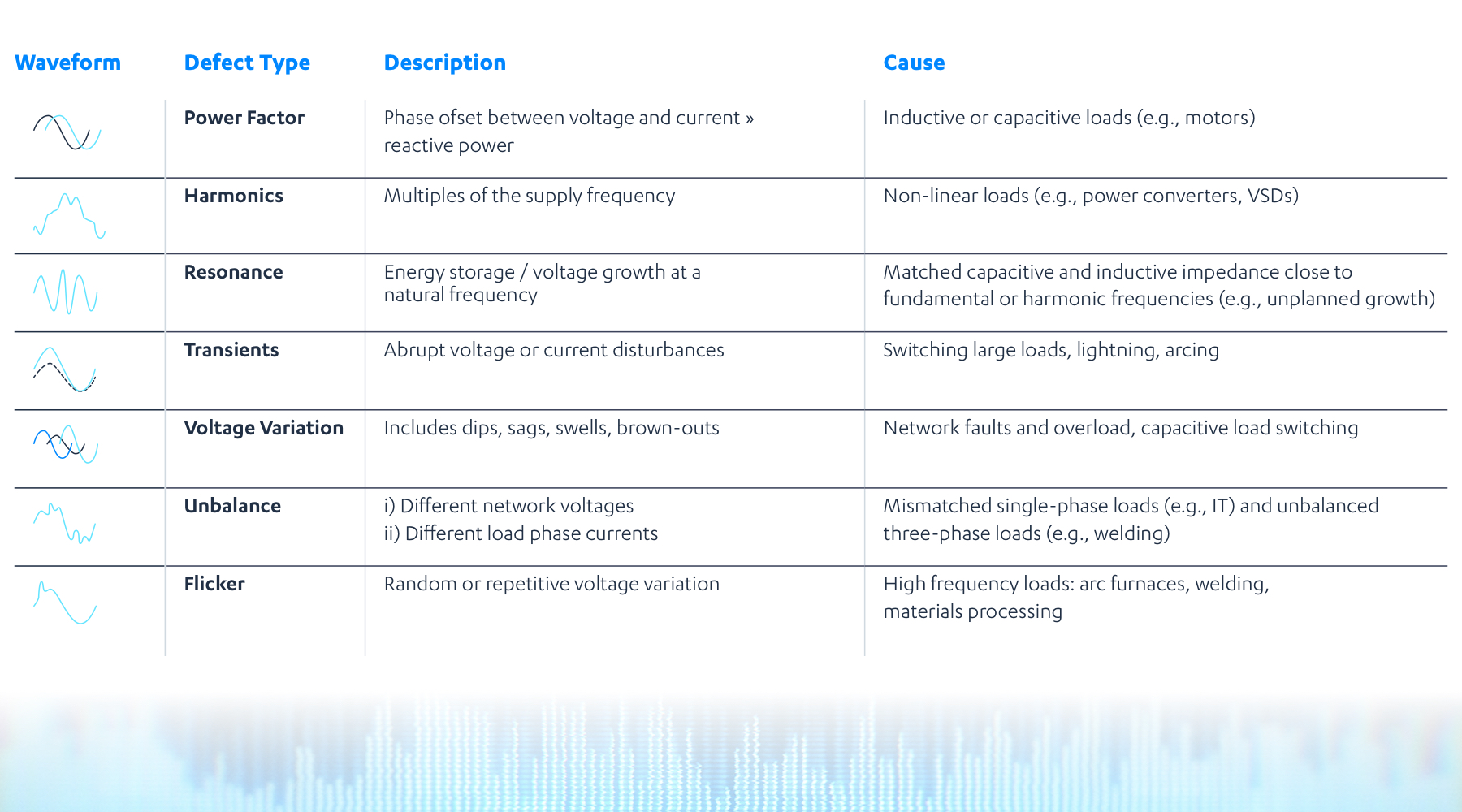

Non-linear loads created by these modern technologies — e.g., switched-mode power supplies, variable speed drives, renewable energy sources, AC-to-DC converters and others — cause changes in the composure of electricity. Sine waves become distorted, with different rhythm and magnitude characteristics. These distortions cause unexpected voltage variations — including harmonics and supraharmonics, load imbalances, low power factor that draws utility penalties, and a host of other technical issues. (See figure 1.)

Figure 1: A summary of different types of power quality disturbances and how they manifest in waveform distortion and data.

How waveform distortions show up at work:

- Voltage sags can cause sensitive electronics to cycle on and off or suffer damage. Other consequences include inefficient energy consumption, low power factor and data loss.

- Transient overvoltage from a large capacitor bank installation can make its way to a smaller capacitor bank meant to support an operations process. The magnified transients lead to nuisance tripping, and ultimately equipment damage.

- Harmonics introduced by a solar farm upstream on the grid can interact with nearby capacitors supporting a large high-speed EV charging station. This produces supraharmonic-level voltages and currents as well as resonant frequencies. The result: Increased system harmonic distortion beyond compliance limits, and shortened asset lifetime.

The key to preventing power quality issues?

Enterprise visibility.

Many instruments on the market measure power quality from metering data at individual points of consumption. However, to understand where your operations may be prone to disruption from power quality issues, you need precise and actionable insight into real-time system behaviors, patterns and trends across your enterprise, as well as changes at the grid edge.

For example, QubeScan, our intelligent, secure cloud platform, enables our customers to collect and analyze data from all Powerside PQube® 3 and PQ Edge® analyzers, anywhere in the world, 24/7. With the touch of a button, QubeScan users can produce and share reports to direct preventive measures and mitigate further business impacts. Meanwhile, when a new solar site or inverter comes online, QubeScan can alert to these new impacts, keeping you in step with changing load profiles.

Your business can’t afford the uncertainty of trial and error diagnosis.

Quickly home in on power quality with systemwide data and analytics. Request a QubeScan demo today.

1 Electric Power Research Institute (EPRI), Inc. PQ TechWatch: Societal Costs of Power Quality Disturbances, July 2022