Case Study

The high-tech electronics that power data centers, medical imaging and other mission-critical applications are finely tuned machines. But subpar power quality from the supply powering those machines can lead to equipment outages, damage, unreliable performance, safety hazards and costly service calls.

The PQ Edge® power quality monitor delivers essential power measurement at an affordable price. Perfect for OEMs looking to add power monitoring to their equipment or facility managers seeking straightforward power tracking—the PQ Edge delivers.

Perfect for equipment manufacturers looking to add power quality monitoring without significant cost impact.

Ensure reliable power for life-critical medical equipment including MRI, CT scanners, and surgical systems.

Ideal for small to mid-size facilities and equipment who need affordable power quality monitoring and analytics without complexity.

For industries and applications requiring ultra-precise measurements and comprehensive analytics explore our PQube 3 Power Analyzers.

Avoid costly service calls by identifying root causes before equipment failures occur. Prevent downtime and extend equipment life.

Historical trend analysis and custom alerts enable preventive measures before problems escalate into costly outages.

Interactive charts and custom reports provide executive stakeholders with insights to inform strategic decisions.

Unobtrusive design allows facility managers to install in a few simple steps. Perfect for embedded OEM applications.

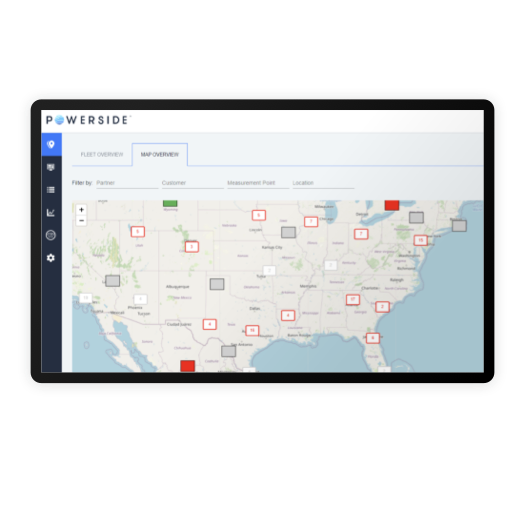

When used with QubeScan's secure AWS platform, get fleet-wide monitoring from anywhere.

Boost productivity of critical capital-intensive assets through proactive power quality management.

Use PQ Edge with our QubeScan monitoring software to effortlessly manage power quality across a fleet of equipment. PQ Edge collects real-time data at the local level. QubeScan's secure AWS cloud-based platform ingests the data from all your PQ Edge units and other power analyzers for fleetwide charts and dashboards, analyses and stakeholder collaboration.

| Parameter | Specification |

|---|---|

| HMI Display | Companion iOS® or Android™ app to interface with device, Bluetooth® connectivity, operation LED (flash mode), USB for data download |

| Weight | 8.4 oz. |

| Dimensions (L x W x H) | 5.52 x 3.78 x 2.38 in. |

| Voltage Channels | 4 voltage, up to 690V nominal |

| Current Channels | 4 current channels (333mV) |

| Analog/Digital/Relay/ENV Sensor | 1 X ENV2 probe for temperature, humidity, barometric pressure and 3-axis acceleration sensor |

| Memory & Storage | 32GB internal storage, USB port, and cloud storage |

| Instrument Power Requirement | 24 VAC or 24-48VDC |

| PQ Sample Rate & Class | 512 samples/cycle @ 50/60Hz Class A |

| Harmonics; THD, TDD, THDI | IEC 61000-4-7 Cl 1 up to 50th |

| Conducted Emissions Supraharmonics |

Range: 2 to 9 kHz 0 to 60Vpk, 200Hz bins |

| Power & Energy Class | kWh Accuracy Cl 0.5 kVARh, kVAh, PF (DPF or TPF) |

| Flicker | IEC 61000-4-15 |

| High-Frequency Impulse | Not available |

| Unbalance | IEC, GB and ANSI methods |

| Communication Protocols | Modbus/TCP, DNP 3.0, SNMP with traps, BACnet, FTP or HTTP (secure FTPS and HTTPS, and email) |

We've helped companies ranging from Fortune 500 enterprises to leading startups with innovative power quality solutions.

Review All Case Studies & Application NotesUse PQ Edge with our QubeScan monitoring software effortlessly manage power quality across a fleet of equipment. PQ Edge collects real-time data at the local level. QubeScan’s secure AWS cloud-based platform ingests the data from all your PQ Edge units and other power analyzers for fleetwide charts and dashboards, analyses and stakeholder collaboration.

The PQ Edge is designed to be unobtrusive. Facility managers can install it on the electrical system in a few steps, and it stays out of the way. For OEMs, it fits nicely as an embedded, value-added enhancement within the machine.

Stay attuned to voltage, current, frequency and waveform characteristics like dips, swells and other parameters so you can take preventive measures before problems escalate. Keep tabs on environmental conditions with our ENV2 probe.

An equipment malfunction may really be a power quality issue. Avoid the cost and friction of troubleshooting and equipment service calls by correctly identifying root causes.

Tap into historical trends, produce custom reports and share interactive charts with executive stakeholders to inform strategic decisions.

Proactive power quality management can reduce damaging events and boost productivity of critical capital-intensive assets.

A healthy power supply is the key to reliable, productive, efficient operations. PQ Edge helps set you up for success.