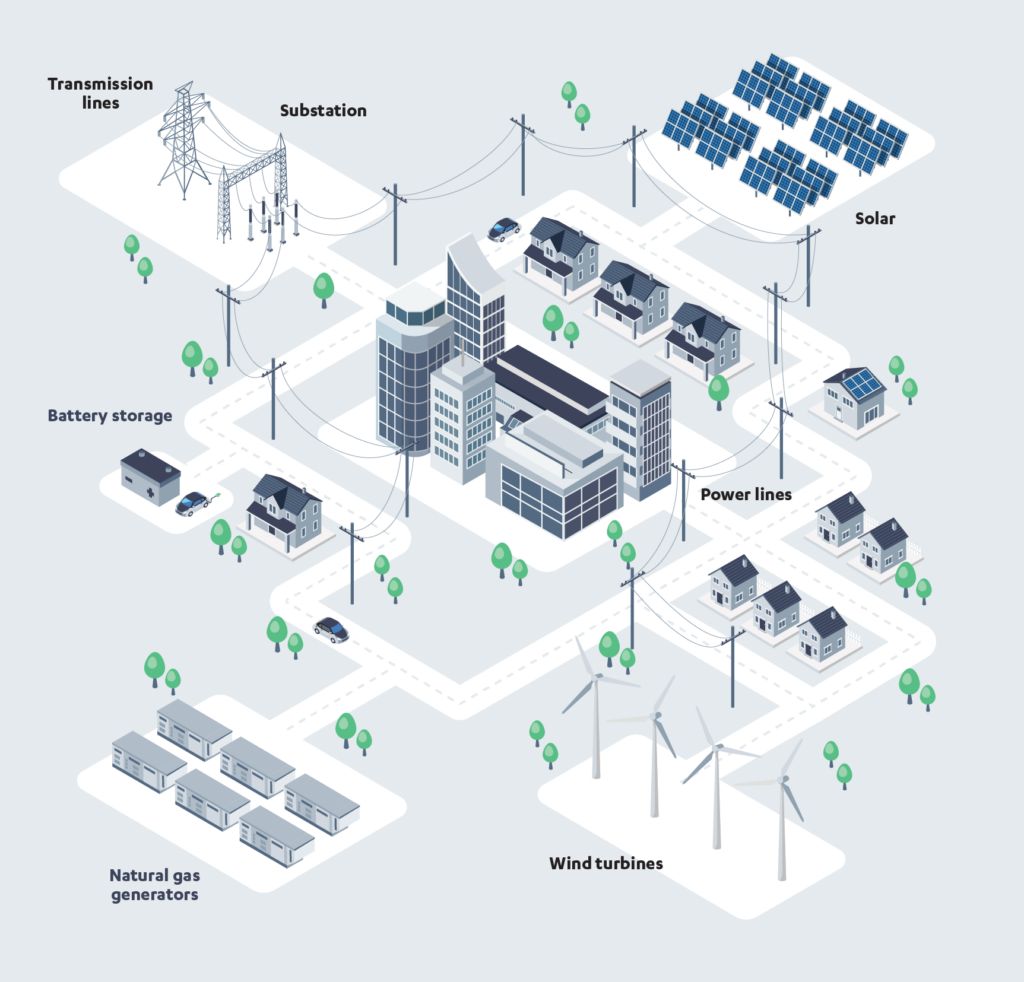

As innovation at the grid edge continues, utilities face increasing pressure to maintain an efficient and reliable power supply. This is especially true for grids with a high capacity of distributed energy resources (DERs), such as wind and solar generation, which more acutely affect the grid with their performance-disrupting anomalies.

To improve reliability across the grid, many utilities deploy advanced sensor systems that monitor electrical parameters, identify anomalies and alert when corrective actions are needed. Sensors can enable utilities to collect dynamic power quality measurement and real-time synchrophasor voltage and current data from multiple locations — yielding the clearest picture of how DERs impact the grid around the clock.

While advanced sensor technology can provide the invaluable information utilities need to manage the grid, this data can be compromised by a number of influences — including the affiliated components in the sensor system, environmental conditions and proximity to external electrical fields. Unfortunately, it is difficult for engineers to anticipate the full spectrum of factors that could impact sensor-measuring capabilities until the sensor systems are deployed in real-world application.

Engineers and technicians tasked with installing sensor systems need a common framework for evaluating system performance.

Until standards are introduced by the standards institutions, conditional accuracy should be considered when testing and evaluating sensor system performance.

Conditional Accuracy is Becoming a Factor in Smart Grid Development

According to IEEE Technical Report PES-TR102, MV Smart Grid Sensor and Sensor Systems: Measurement Accuracy and Uncertainty Considerations, conditional accuracy is a metric used to quantify a sensor or sensor system measurement performance — factoring in operational influences on the system such as environmental conditions and external electrical influences.

In other words, conditional accuracy provides a metric on how well the sensor system can measure electrical parameters under various operating conditions.

Without conditional accuracy, engineers and technicians have difficulty clarifying the true performance of sensor systems in the various environments they’re installed in. Additionally, each system component and sensor may be tested and manufactured as a singular component under a controlled range of laboratory conditions — not as a system.

By incorporating a conditional accuracy evaluation and system testing into the performance assessment, utilities can better understand the reliability and limitations of their sensor system measurements.

Why are Sensor System Measurements Easily Affected?

To fully understand the factors that can affect measurements, it is vital to first understand sensor system components.

The sensor system physically includes:

- The sensors (with active or passive measuring elements)

- Intelligent electronic devices (IEDs) that process values (e.g., power analyzers)

- Cables of specified length/type

- Communications

Each component comes with its own manual and particular characteristics, such as accuracy class/performance, operating range and temperature rating. However, any of these specifications may be affected by the encompassing sensor system — e.g., voltage and current measurement ability, crosstalk induction and any relevant signal processing.

Take, for instance, the sensor burden and input impedance of an IED. If there is a mismatch between these respective values, it can negatively impact the accuracy of a sensor system’s reading.

There are various factors that can impact individual sensor system components and their analog measurement circuits in different ways. These include but are not limited to:

- Sensor and IED impedance matching

- Shielding along the sensor signal chain (e.g., sensing elements within sensor, cable design)

- Local temperature fluctuations and extreme weather

- External electric field disturbances

- Operating measurement range

- Timing and latency issues

Each sensor system component will also be influenced by the communications network. Latency, communication protocol and network design are all operating influences that may impact the sensor’s measurement performance.

Ultimately, it may be challenging for lab testing to cover every possible factor that can impact sensors. There are many circumstances and influences that are part of the equation, and careful consideration should be taken to ensure the sensor system solution is suitable for the application.

How can Technicians Safeguard Against Flawed Power Measurement Readings?

Given how many factors can skew sensor readings, it is important to work with manufacturers that have performed applicable type testing or have conducted effective pilot and field testing that mimics the rigor of the installed environment. Doing so helps to account for factors such as environmental conditions, aging and faults, thus allowing for more accurate measurements moving forward.

Test-scenarios and applications to consider include:

- Real-world conditions

- Existing use cases (or applications) of interest

- Reliable comparison references (e.g., other sensors with proven, comparable field and laboratory performance)

Accurate measurements of electrical parameters in power grids are critical for ensuring a reliable power supply. By using the conditional accuracy approach to assess the measurement of electrical parameters, power utilities can more accurately monitor grid performance and improve power reliability and efficiency.

To learn more about considerations for testing and deployment of smart-grid sensor systems, read the IEEE technical report prepared by the IEEE PES PSIM Sensors Task Force.