Throughout the semiconductor industry, Powerside products and services help keep process interruptions to a minimum. Toolmakers depend on Powerside power quality monitors like the PQ1 power quality sensor and PQube® 3 power analyzer, as well as the Powerside SEMI F47 testing services for voltage sags. Here’s how they are using these solutions to their advantage.

PQ1 Power Quality Sensor

This compact power quality sensor detects sags, swells, interruptions and impulses as short 500 nanoseconds — disturbances that significantly disrupt equipment. The PQ1 quickly integrates into a semiconductor tool and can be DIN-rail or panel mounted.

Key features of the PQ1:

- Very low cost

- Simple to install: AC in, relay contacts out

- Built-in SEMI F47 curves

- No software or computer required

- Designed with 3 pairs of normally closed dry relay contacts, which open for each power quality event and then reclose at the end of the event

- Use the relay contacts like any switch contact: Control relays, activate alarms, trigger inputs in a control system, insert entries in the system’s error log

- Thousands of units deployed in the semiconductor industry over 15+ years

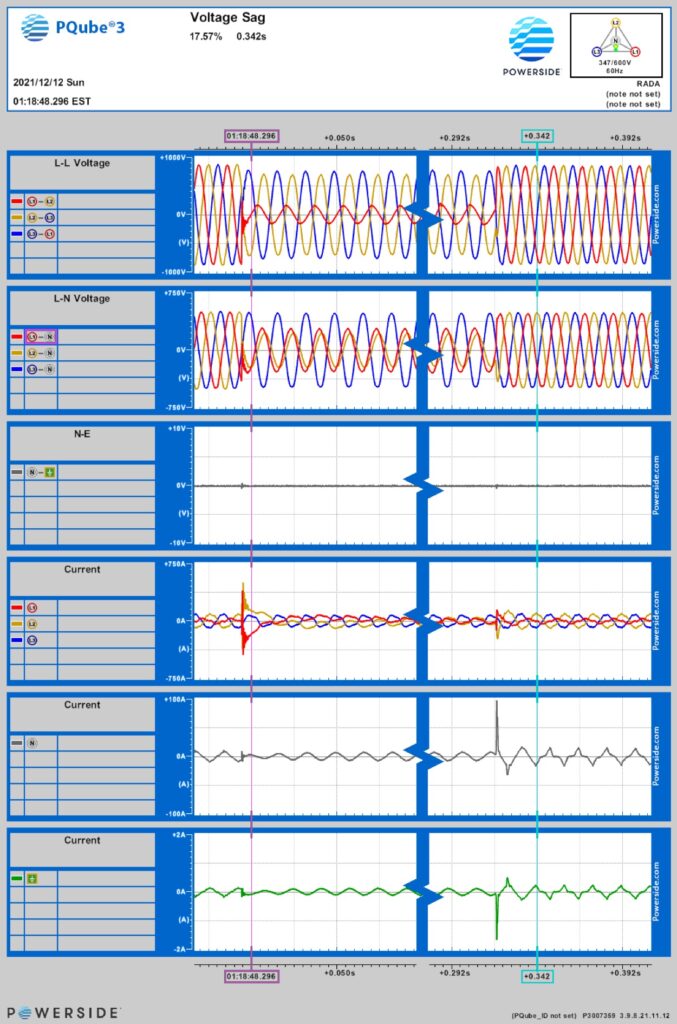

PQube 3 Power Quality Monitor

Powerside’s rugged and robust power quality monitor has been optimized for use in and around semiconductor fabrication tools, drawing an enthusiastic fan base in the industry.

Because power quality events are a common occurrence at fabs — but not always the problem — the data captured by the PQube 3 proves valuable in investigating a tool outage and quickly proving (or ruling out) power as the cause.

Key features of the PQube 3:

- Monitor power quality, tool performance and (with added module) environmental conditions in real-time using embedded remote communications via secure HTTPS and FTP-S

- The ENV2 environmental module monitors temperature, humidity, pressure and vibration

- Can be easily embedded inside the tool: Unit is small and can mount on DIN-rail inside the tool and still communicate via multiple protocols

- Instant installation and startup: Once the PQube 3 is installed and powered up, it auto detects the nominal frequency, voltage and wiring configuration, saving time and money on commissioning

- Automatic reporting features including time-stamped events and reports

- Reports are presented in an easy-to-read format and in multiple languages

- Avoids the problem of field technicians making “false replacements” that are expensive and unnecessary

- Power profiling feature keeps tabs on the power usage of your tool

- Helps you sell more tools: By knowing the actual peak power requirements, the customer can consider allocating tool

- Easily generates SEMI F47 compliance reports to show daily/monthly compliance of the power supply

Industrial Power Corruptor (IPC)

Invented by Powerside and manufactured in the U.S., the IPC intentionally produces bad quality electric power, reliably and repeatedly.

Key features of the IPC:

- Used for SEMI F47 and SEMI E6 testing

- Generates voltage sags and swells that can be used to test whether semiconductor tools can sag

- Can also be used to troubleshoot a tool that does not ride through a sag, by using its onboard digital oscilloscopes and meters

- Very limited supply of IPCs available for sale; see our SEMI F47 Testing Services as an alternative

SEMI E6 (Part 12) Testing Services

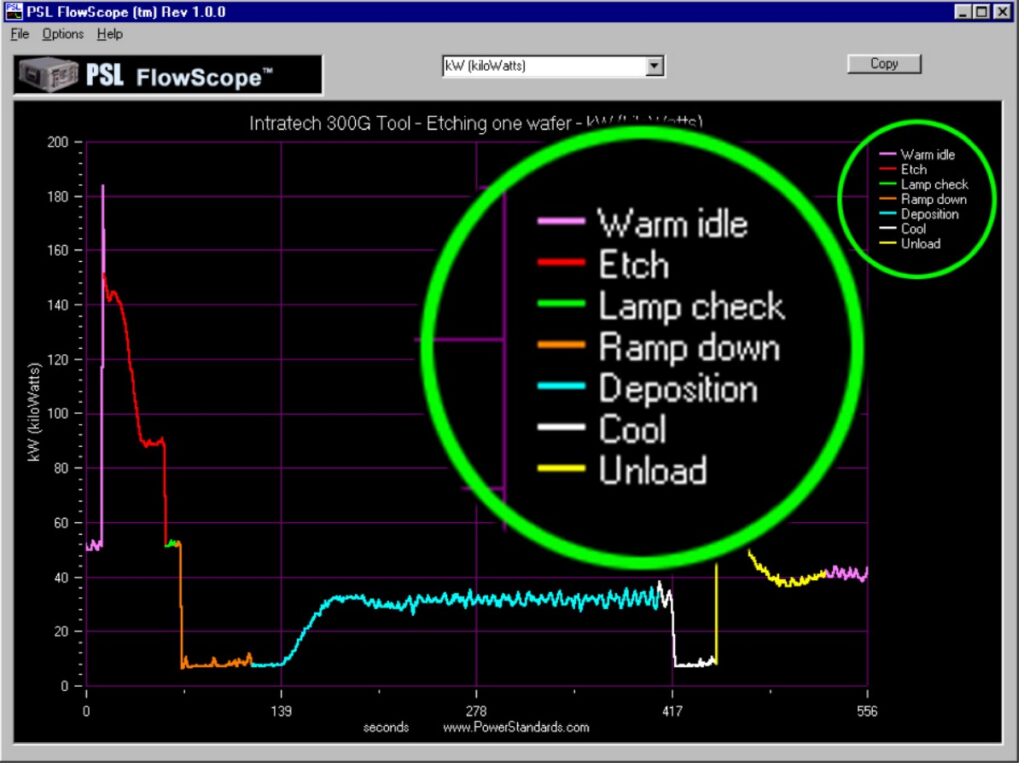

Many leading tool purchasers are now requiring SEMI E6 testing. Part 12 of this testing requires complete information about electricity consumption per wafer, graphs of kW, kWh, kVA, power factor, THD, harmonics and more.

- Using the IPC at your site, Powerside can perform the testing required for Part 12 of SEMI E6, and produce plots of power versus time

- This testing service can be done in conjunction with SEMI F47 testing the same day

- Power characterization plots can easily be generated using the IPC and its Power Flow Analysis software — plotting power versus time over the entire batch

- Discrete cycles in the recipe can be labeled on the power characterization plot

SEMI F47 Testing Services

Per SEMI F47-0706, “Semiconductor factories require high levels of power quality due to the sensitivity of equipment and process controls. Semiconductor processing equipment is especially vulnerable to voltage sags.”

SEMI F47 testing helps you certify that your tool, or tool component, is ready for use in semiconductor fab:

- A successful test will demonstrate that your tool can ride through various voltage sags that the tool may encounter in real-world conditions

- Powerside can perform SEMI F47 testing at your location using our own IPC for the testing, providing reports and certificates of how the tool performed

Have a power quality challenge plaguing your operation?

We get questions all the time from semiconductor manufacturers.

We’d love to help you.

Contact Us

United States

980 Atlantic Ave

Alameda (CA) 94501

1-888-736-4347

Canada

7850 Trans-Canada Highway

Saint-Laurent (QC) H4T 1A5

1-877-333-8392